-Рубрики

- БЛЮДА ДЛЯ ПИКНИКА (5)

- РЕЦЕПТЫ ДЛЯ МАНГАЛА (5)

- ВНУТРЕННИЙ АУДИТ/INTERNAL AUDIT (4)

- ВНУТРЕННИЙ КОНТРОЛЬ/INTERNAL CONTROL (11)

- Flowchart (9)

- Risk management (2)

- ВСЕ ДЛЯ БЛОГА И ДНЕВНИКА (402)

- Анимашки/клипарты (35)

- Генераторы текста (29)

- кнопки ДАЛЕЕ (22)

- КОММЕНТИКИ/НАДПИСИ (21)

- открытки-пожелания (16)

- помощь начинающим (129)

- Разделители для блогов (32)

- рамочки (118)

- схемы оформления (4)

- флэш бродилки (7)

- ВСЕ ДЛЯ ДОМА (166)

- ИДЕИ ДЛЯ УСАДЬБЫ (135)

- ИНТЕРЬЕР (15)

- Кухонная посуда/инвентарь (1)

- ОГОРОД (16)

- ВТОРЫЕ БЛЮДА (262)

- БЛЮДА В ГОРШОЧКАХ (5)

- Блюда в фольге (5)

- Блюда из грибов (21)

- Блюда из круп и бобов (3)

- Блюда из макарон (5)

- Блюда из мяса и птицы (102)

- Блюда из овощей (125)

- Блюда с рыбой/морепродуктами (9)

- ВЫПЕЧКА (1437)

- БЛИНЫ/БЛИНЧИКИ/Панкейки (62)

- Рецепты для Хлебопечки (29)

- Булочки/рогалики (76)

- вареные изделия из теста (18)

- жареные во фритюре изделия (119)

- Мафины и кексы (65)

- НЕСЛАДКАЯ ВЫПЕЧКА (48)

- ПЕЧЕМ ХЛЕБ (15)

- ПЕЧЕНЬЯ (492)

- пироги несладкие (52)

- пироги сладкие (89)

- ПИРОЖЕНЫЕ (224)

- пицца (9)

- РУЛЕТЫ (39)

- Секреты выпечки (6)

- СЛАДКАЯ ВЫПЕЧКА (43)

- СПОСОБЫ РАЗДЕЛКИ ТЕСТА (38)

- Тарталетки (33)

- ДЕСЕРТЫ (97)

- ЖЕЛЕ (15)

- Конфеты (4)

- Мороженное (5)

- РАЗНЫЕ ДЕСЕРТЫ (41)

- Суфле (24)

- Фруктово-ягодные десерты (11)

- ДЕТСКИЕ БЛЮДА (6)

- ДЛЯ ДУШИ (300)

- Motivational area (58)

- Интересно (29)

- YOGA (1)

- МУЗЫКА ДЛЯ ДУШИ (123)

- СТИХИ для ДУШИ (23)

- ТАНЦЫ (22)

- ЦИТАТЫ (7)

- ЮМОР (37)

- ЖЕНСКОЕ (86)

- ЗАНИМАЕМСЯ С ДЕТЬМИ (1)

- КАРЬЕРА (11)

- Кладовая советов (33)

- макияж/маникюр (2)

- маски для лица (2)

- МАТЕРИНСТВО (9)

- МОДНИЦА (7)

- ПРИЧЕСКИ (13)

- Про женские особенности (5)

- трафареты (3)

- ЗАВТРАКИ (62)

- Запеканки (19)

- РАЗНОЕ (30)

- яичница и ее "родственники" (14)

- ЗАГОТОВКИ НА ЗИМУ (20)

- Варенье/ Компоты/Соки (13)

- Закуски на зиму (4)

- Заморозка на зиму (1)

- Маринование/соления (1)

- Сушка овощей и фруктов (1)

- ЗАКУСКИ (101)

- Домашний сыр/творог (2)

- Закуски из грибов (7)

- Закуски из мяса и птицы (42)

- Закуски из овощей (13)

- Закуски из рыбы/морепродуктов (10)

- Закуски из хлеба (1)

- Закуски из яиц, сыра и творога (8)

- Закуски на шпажках (2)

- ЗАКУСКИ ПРАЗДНИЧНЫЕ (11)

- Закусочный торт (2)

- Паштет (3)

- Роллы (1)

- Холодец, Заливное (6)

- ЗДОРОВЬЕ (60)

- Восстановление энергии (3)

- НАРОДНАЯ МЕДИЦИНА (12)

- очищение организма (1)

- полезное (22)

- ПОЛЕЗНЫЕ ПРОДУКТЫ (9)

- УХОД ЗА ТЕЛОМ (13)

- чудеса бывают (4)

- ИЗУЧАЕМ АНГЛИЙСКИЙ ЯЗЫК (135)

- КНИГИ (58)

- Аудиокниги (2)

- бродилки кулинарные (25)

- Журналы по кулинарии (22)

- КНИГИ (2)

- энциклопедии (6)

- КОМПЬЮТЕР (78)

- компьютер для новичков (28)

- НУЖНЫЕ САЙТЫ/ПРОГРАММЫ (50)

- КУХНЯ НАРОДОВ МИРА (6)

- МИР ВОКРУГ НАС (29)

- Интересно (5)

- Красота/достопримечательности (24)

- Туризм/путешествия (5)

- МОЙ ГОРОД (3)

- Национальные блюда/Молдавская кухня (2)

- о моем городе (1)

- НА СКОРУЮ РУКУ (133)

- БЛЮДА ИЗ ЛАВАША (28)

- Полуфабрикаты домашние (2)

- ИЗ СЛОЕНОГО ТЕСТА (89)

- ИЗ ТЕСТА ФИЛО (4)

- ЛАЗАНЬЯ (4)

- РАЗНЫЕ БЛЮДА (7)

- НАПИТКИ (26)

- Алкогольные напитки (16)

- Горячий шоколад (1)

- Кофе (6)

- Молочный коктейль (4)

- ПЕРВЫЕ БЛЮДА (1)

- ПОСТНЫЙ СТОЛ (9)

- Вторые постные блюда (4)

- Постные первые блюда (1)

- Постные пироги (1)

- Постный десерт (3)

- ПРАЗДНИКИ (127)

- День рожденья (4)

- Для детского праздника (5)

- Новый год и Рождество (65)

- Пасха (21)

- Поздравления (1)

- ПРАЗДНИЧНЫЕ БЛЮДА (17)

- Сервировка стола (3)

- Тосты (1)

- УКРАШЕНИЕ БЛЮД (22)

- ПРО ДЕНЬГИ (7)

- ПСИХОЛОГИЯ (142)

- Public speaking (7)

- Живи и радуйся жизни! (7)

- МУДРЫЕ МЫСЛИ/МУДРОСТЬ ЖИЗНИ (32)

- Релакс (25)

- Саморазвитие (40)

- РЕЦЕПТЫ ДЛЯ МУЛЬТИВАРКИ (5)

- РЕЦЕПТЫ ДЛЯ ПАРОВАРКИ (2)

- РУКОДЕЛИЕ (130)

- аксессуары (22)

- Скрапбукинг (1)

- БУКЕТЫ ИЗ КОНФЕТ (2)

- ВЯЖЕМ КРЮЧКОМ (47)

- денежные конверты (2)

- открытки (11)

- Подарки, праздничные поделки (34)

- упаковка подарков/коробочки (9)

- САЛАТЫ (95)

- Овощные салаты (3)

- Подборка САЛАТОВ (18)

- САЛАТЫ ПО-КОРЕЙСКИ (14)

- Салаты с грибами (7)

- Салаты с курицей (32)

- Салаты с мясом (7)

- Салаты с рыбой и морепродуктами (14)

- Салаты с сыром или творогом (4)

- СЕКРЕТЫ ПРИГОТОВЛЕНИЯ БЛЮД (38)

- Как быть, если... (1)

- кулинарные премудрости (27)

- пряности, специи (2)

- таблица массы и объемов продуктов (7)

- СОУСЫ,ЗАПРАВКИ (4)

- Домашний кетчуп (1)

- Домашний майонез (1)

- Соусы и заправки для салатов (1)

- ТЕСТО (115)

- Дрожжевое тесто (36)

- Заварное тесто (4)

- Песочное тесто (6)

- Подборка (53)

- СЕКРЕТЫ ДЛЯ ТЕСТА (4)

- Слоёное тесто (12)

- ТЕСТЫ (6)

- ТОРТЫ (1075)

- без выпечки (80)

- бисквитные (227)

- глазурь для торта (13)

- из заварного теста (45)

- коржами (158)

- крем, пропитка для торта (45)

- МИНИ-ТОРТИКИ (1)

- мусс, желе (243)

- наполеон (34)

- ПЛЯЦКИ (12)

- Подборка (13)

- птичье молоко (18)

- тирамису (15)

- ТОРТ-МОРОЖЕНОЕ (6)

- УКРАШЕНИЯ ТОРТА (36)

- фруктовые (55)

- ЧИЗКЕЙКИ (70)

- УЧИТЬСЯ и УЧИТЬСЯ (2)

- ЦВЕТЫ И РАСТЕНИЯ (49)

- Декоративные растения - сад (43)

- комнатные цветы (6)

-Поиск по дневнику

-Статистика

Записей: 5137

Комментариев: 101

Написано: 5294

Process Maps |

Description:

Process Maps are detailed flow diagram of the process using color coded symbols that drill further into the high level map generated on the SIPOC.

The purpose is to visually represent the process as it is in reality. Complete the current state map by walking (GEMBA walk) and experiencing the process. This is a valuable learning experience, the team will quickly gain insight about the actual flow. Don’t sit in a room and think it through yourself or with the team. Patience, time, asking questions are all part of the completing this map.

Create a current state and a future state. Your team may want a future state with a short term target (such as 90 days) and a long term ideal state.

Objective:

To capture all the complexity and improvement opportunities by analyzing each step in detail. Seek out the 7-Wastes and enhance current value-added activities.

Levels of a Process Map

Look for:

- Automation Opportunities

- Material Handling

- Duplication

- Redundancy

- Decisions

- Delays

- Rework Loops

- Non-Value Added Steps vs. Value-Added Steps

These represent opportunity for waste elimination. Proceed with the goal to eliminate waste before settling for waste reduction. Throughout the entire process map, look for the 7-Wastes. So, before process mapping, educate the team on how to "see" waste.

Take caution when considering "automation" to take over manual processes. People are adaptable and much more flexible. Automation is fixed, constant, and often difficult to fix and maintain. In a JIT environment the decision to automate is advised with caution.

This map is considered a living document. It is meant to be reviewed and updated on a continuous basis. The more detail it contains, the better understanding you and the team will have of the true process and opportunities.

Peanut Butter & Jelly Process Map Example

A good process map gets the process from the 50,000 foot level to the ground level of the actual process.

The development of the map is a team effort and it will educate everyone on the reality of the process and most often how little of the total process is value added. Typically, there are obvious improvements that will be become evident while the mapping is being done.

It will not be perfect the first time through, add more detail as it evolves. It is important to remain with the Start and Finish boundaries set forth by the SIPOC in the DEFINE phase.

The team needs to begin identifying the value added steps versus the non-value added steps and time. This realization is clearer during Value Stream Mapping (VSM) that adds more quantification to the steps.

Creating a future state or ideal state (while being realistic yet not too limited) will make it clear to the team that everything getting in the way is opportunity to improve. Laws, regulations, customer standards, past paradigms all need to be challenged because they change over time.

Creating a process map on a computer is common and many software programs exist that have symbols created. However, the first drafts are often very complex and frequently revised.

Create the real flow on paper and post it publicly for others to offer input and critique. It is very important to catch the rework loops, communication issues, decision delays, stops, starts, pick-ups, drop-offs, and other waste so the team fully understands the opportunities.

These hidden factory "what-if" and "sometimes" paths are important for everyone to document and understand. This knowledge will create better subjective decisions when assigning weights to the inputs using the subjective root cause analysis tools in theMeasure phase.

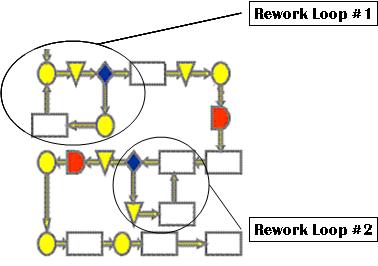

Rework Loops

Rework loops are where defects and wasted time are occurring. The team should focus on preventing them, reducing their severity, and detecting them if they can not be eliminated.

Some product or process may actually go through the rework path multiple times and the map does not illustrate this unless specially noted and discussed.

The picture below shows two Rework Loops. Rework loops have varying severity. The process map does not show the amount or cost of pieces scrapped or the amount or cost of pieces reworked. Use the yield calculations to get this data.

Often a Rolled Throughput Yield (RTY) is calculated to help quantify the scrap and rework through these loops and this does not always mean the lowest RTY is the worst financially or to the customer.

If one type of rework is more expensive or higher risk to the customer (such as a delayed delivery), then it may be a higher priority to improve. This is all going to shake out in the subjective root cause analysis tools and the inputs get funneled out to the most important, key process input variables (KPIV's).

Insurance companies will often use flowcharts to identify hazards or perils that could result in exposure. Flowcharts should also be used by the team to evaluate ideas to reduce these exposures, similar to reducing the severity, occurrence, and detection of an input within aFMEA.

Risk managers often use them along with questionnaires for employees, inspections, and statistical analysis of previous losses to establish premiums for the company. Have an internal Risk Manager sit on your team from your company may be another way to capturefinancial savings.

Through a careful and detailed inspection process the best overall risk assessment can be done. Process Maps can provide a lot of information in an easy to read format. They will be looking for potential problems that are a combination of hazards, perils, and exposures.

For example:

A Six Sigma team may be working to reduce the number of Recordable Injuries and Lost Time Injuries. Some improvements that may be implemented are alarm systems, sprinklers in new areas, facility-wide intercoms, and others that may also qualify your company for reduced property insurance premiums.

Create a Process Map in Excel

|

|

|

Value-Added vs. Non-Value Added

Theoretically, the perfect state of a value stream or flowchart is to have 100% of the steps adding value.

What does this mean?

Value-Added:

- Physical change in the product

- Customer is willing to pay for the step or service

- First time yield is 100% - done right the first time

There is some debate about compliance steps. Certain steps are done to meet compliance criteria such testing and documentation. There is usually opportunity to streamline this "regulatory" or "business-mandated" processes.

The team should review these and not simply accept that they are requirements. Challenge the process and rule, ensure that the rules have not changed and get evidence of the rule to validate. Perhaps, the current method has waste or even the requirement is not being met.

Non-Value-Added:

- Set-ups

- Preparation

- Meetings

- Any of the 7-Wastes

- Inspections (that are not "business or regulatory" requirements

- Not necessary to add value to the product or service

- Customer is not willing to pay for the step

Process Mapping - Download

|

This module provides lessons on how to use different types of process mapping tools to breakdown and understand your business processes. It also gives an insight of how the outputs from this tool can become critical inputs for the more advanced tools you may use through your DMAIC journey.

|

Flowchart Symbols

Different sources will use suggest different colors denotations for symbols. The color will help to identify specific steps when looking at very detailed maps. It is important that your teams uses a consistent color scheme. There are hundreds of symbols, some of the most common are shown.

Variations

Several other visual tools are forms of Process Maps and each has a specific use, is a part of another tool, or is a type of process map.

For example, the SIPOC is more than a very high level process map, it defines the Suppliers, Inputs, Outputs, and Customers and its "Process Map" portion is very generic.

Some of these tools are:

-IDEF Modeling

-SIPOC (very high level)

-Deployment Flow Chart - (focuses on hand-off points)

-Value Stream Map (more quantitative but also has limitations)

-Activity Diagram (more detailed than the SIPOC)

-Detailed Process Map (most detailed "ground" level)

-Swim Lane Process Map

Review the SIPOC module

Return to the DEFINE phase

Return to the MEASURE phase

Search active job openings related to Six Sigma

Return to the Six-Sigma-Material Home Page

| Рубрики: | ВНУТРЕННИЙ КОНТРОЛЬ/INTERNAL CONTROL/Flowchart |

| Комментировать | « Пред. запись — К дневнику — След. запись » | Страницы: [1] [Новые] |